Types of Segments

Discover what each segment is suited for.

PCD Segment

Suited for: Removal of light glue

and paint.

Leaving a rougher surface profile on concrete for epoxy keying purposes, Supa Spikes is a shot blaster alternative. They represent the happy medium between a PCD and a metal bond and are perfect for removing light glue and paint (<2mm); however, they are unsuitable for general grinding concrete.

Arrow Segment

Suited for: Removal of thin vinyl glue, carpet glues, light coatings and mortars—aggressive grinding of bare concrete.

Prep concrete and remove the coating, all in one step. Arrow segments pierce light coatings with a sharp leading edge and a 10-degree positive rake. Like a ship’s bow segment, the arrow segments tear and pull away.

Mini Arrow Segment

Suited for: Removal of coatings, epoxy and mastic.

The smaller the arrow, the more aggressive it is. Mini arrow segments tear through coatings and eliminate the gumming up of segments.

double Bar Segment

Suited for: Removal of light

coatings and general concrete prep.

With their angled positioning, Double Bar (V-segments) provide fewer

scratch marks.

Single bar Segment

Suited for: General concrete prep.

It is ideal for removing concrete with a long leading edge. Single bar segments are designed to maximise performance when operating smaller machines. Double bar segments offer longer life and typically perform better under heavier machines. Bar segments are best used up to 80 grit, followed by round D26 segments if you want to move on to less of a scratch profile.

Round Segment

Suited for: General concrete prep.

The round segment is ideal for finer grits with a less leading straight edge, a large surface area and no specific corner.

This design helps minimise deep scratching and excessive gouging, especially on uneven floors.

Rapida Segment

Suited for: Extremely hard trowel, smooth concrete that has been strengthened with curing agents.

During the process, the curing agents form a membrane over the top of the concrete slab, which stops the water near the surface from evaporating too quickly and strengthens the concrete cap. These rigid surfaces require a specific bond that prevents the diamonds from glazing over. Syntec has developed a revolutionary bond for this application, allowing for powerful grinding on even the hardest concrete.

peak Segment

Fits Scanmaskin style plates.

Premium quality diamond tooling view our range of metal bond and PCD options.

X Segment

Unknown

Spiral Segment

Suited for: Removal of soft and abrasive materials like thin set from concrete—general concrete prep.

Spiral cups are used for edging with hand grinders. Fewer segments give more speed, while more segments offer twice the life. If the concrete is softer, more segments are better for removing soft and abrasive materials like thin sets. However, they tend to leave aggressive circles or horseshoe marks. For less scratch, use round D26 segments.

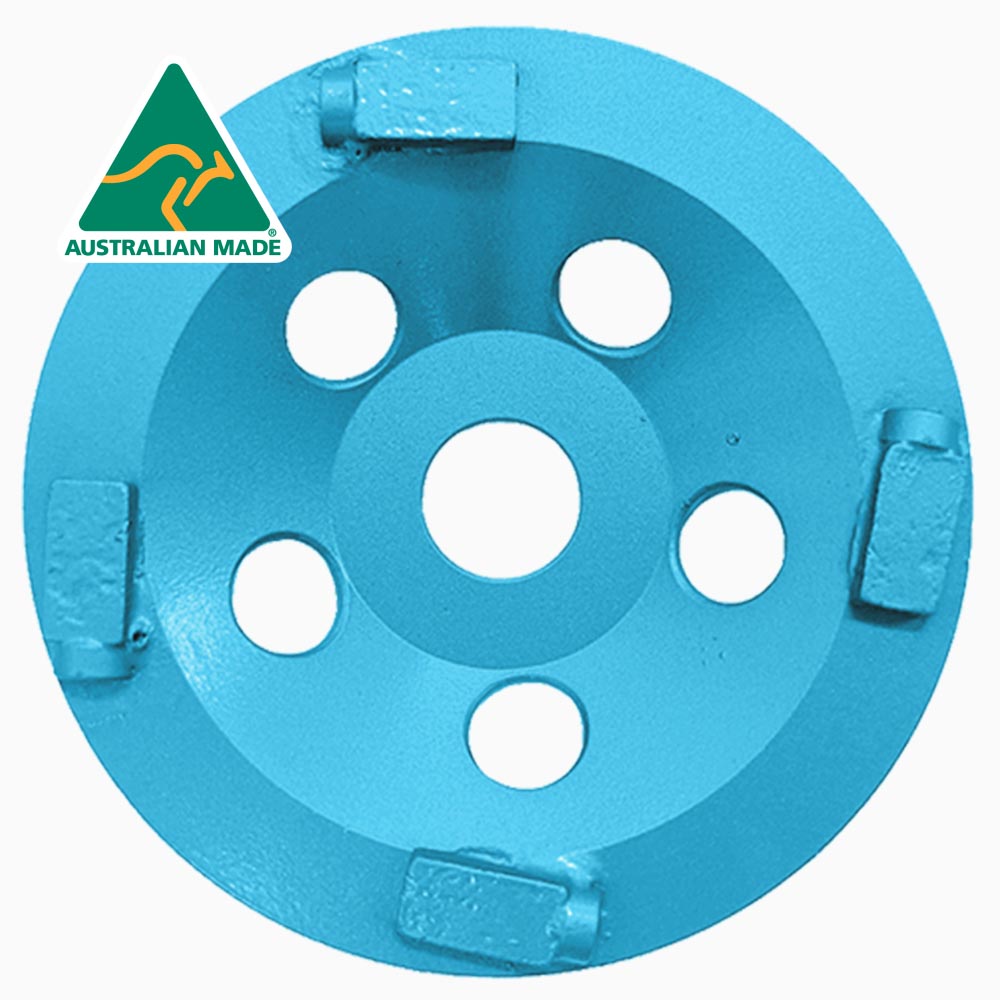

Double Row Segment

Suited for: Grinding of concrete

with bumps and imperfections.

These cups are arranged in a circular pattern and are effective at removing concrete bumps, but can cause noticeable horseshoe marks.

Tornado Segment

Suited for: Aggressive grinding

of concrete.

Tornado cups feature a flat core, allowing for more surface area to place longer segments that reduce gouging even more than spiral cups by not digging in as much. Tornado cups provide aggressive grinding with fewer ring marks, the three and 6-segment models being the most aggressive.

T shape Segment

Suited for: Removal of light coatings and high spots. General concrete prep for coating.

T-cups effectively remove light coatings and leave a smooth concrete surface free of contaminants to create a long-lasting bond with any coating. The T-shaped segments prep edges, reducing gouge marks and eliminating the problem of uneven wear caused by tilting spiral cups.

s shape Segment

Unknown

Super Spike Segment

Suited for: Removal of light glue

and paint.

Leaving a rougher surface profile on concrete for epoxy keying purposes, Supa Spikes is a shot blaster alternative. They represent the happy medium between a PCD and a metal bond and are perfect for removing light glue and paint (<2mm); however, they are unsuitable for general grinding concrete.

Bevel Segment

Suited for: General concrete grinding.

Grinding at a slower rate and tapering, rather than cutting, the bevel shape enables machines to ride smoothly up and over-controlled edges, cracks and expansion joints while minimising chipping and reducing stress to machine gears, couplers and belts. Bevelled edge segments are also ideal when grinding uneven floors while reducing scratch marks.

non-Bevel Segment

Suited for: Light coating removal. General concrete grinding.

Non-bevelled segments add more surface area and grind concrete under heavier machines without leaving scratch marks.

Solid Segment

Suited for: General concrete grinding.

Ideal for straight-out concrete grinding, solid plugs offer excellent results on level smooth surfaces as they leave fewer marks than any segments with a corner.

Metal Resin Hybrid Bond Segment

(Wet and Dry Application)

As the name indicates, metal resin bonds mix metal powders and resins. Metal resins, also known as hybrid bonds, offer double the lifespan of regular resins; hybrids are harder to wear but are only available up to 400 grit. If a higher grit is required, resins are the ideal solution. Unlike ceramics, metal resins can be used wet and dry.

Resin Bond Segment

Similar to metal bonds, resin pads come in varying levels of hardness tailored for different applications, ensuring optimal wear rates of the bond. Resin pads, capable of holding diamonds up to 3000 grit, efficiently eliminate scratches caused by metal bonds, making them ideal for use on hard materials. However, resin pads wear down rapidly on abrasive floors. Avoiding excessive pressure or high machine speeds is crucial, as this can cause the resin to burn. Therefore, limiting the down pressure on each resin pad to 45kg is recommended. It’s important to note that the actual weight of each resin pad depends on several factors, including the number of resin pads, machine balance, and whether the grinder is planetary or oscillating.

Resin Bond Segment

Burnishing pads are natural or synthetic hog hair sprayed with a fine-grit diamond mixed with resin. They are used as the final steps in a polishing process to give an even higher level of shine than what can be achieved by regular polishing with resin diamonds. Often, burnishing pads are used with sealers that protect the floor, for example, against stains from red wine or vinegar spills in supermarkets. The heat generated by the burnishing pads while polishing the floor activates the sealer, forming a protective layer. Burnishing pads are available in a wide selection of diamond grits to cover all applications, from floor maintenance under auto scrubbers to terrazzo and concrete applications under high-speed burnishing machines.

Request a Quote

Syntec Diamond Tools offer a wide range of surface preparation solutions from grinding plates, cups to puck and plugs. We have an extensive range of tooling options to fit any walk behind machine.