Dangers of Silica Dust

Summary

Silica dust is generated from the processes such as crushing, cutting, drilling, grinding, sawing or polishing of natural stone or man-made products that contain silica. This dust can penetrate deep into the lungs and can cause irreversible lung damage.

Managing risks and exposures to silica can be achieved by selecting and implementing the following safety measures:

- isolation of the hazard – designate areas for the tasks that generate dust isolate worker where possible during these tasks. Using enclosures and automation to conduct dust generating tasks.

- Engage controls that minimise the risk of exposure to generated dust, for example, local exhaust ventilation, water suppression (wet cutting) or using tools with dust collection attachments

- Good housekeeping policies, shift rotations and modifying cutting sequences

- PPE (personal protective equipment) including appropriate respiratory protective equipment (face respirator) and work clothing that does not collect dust.

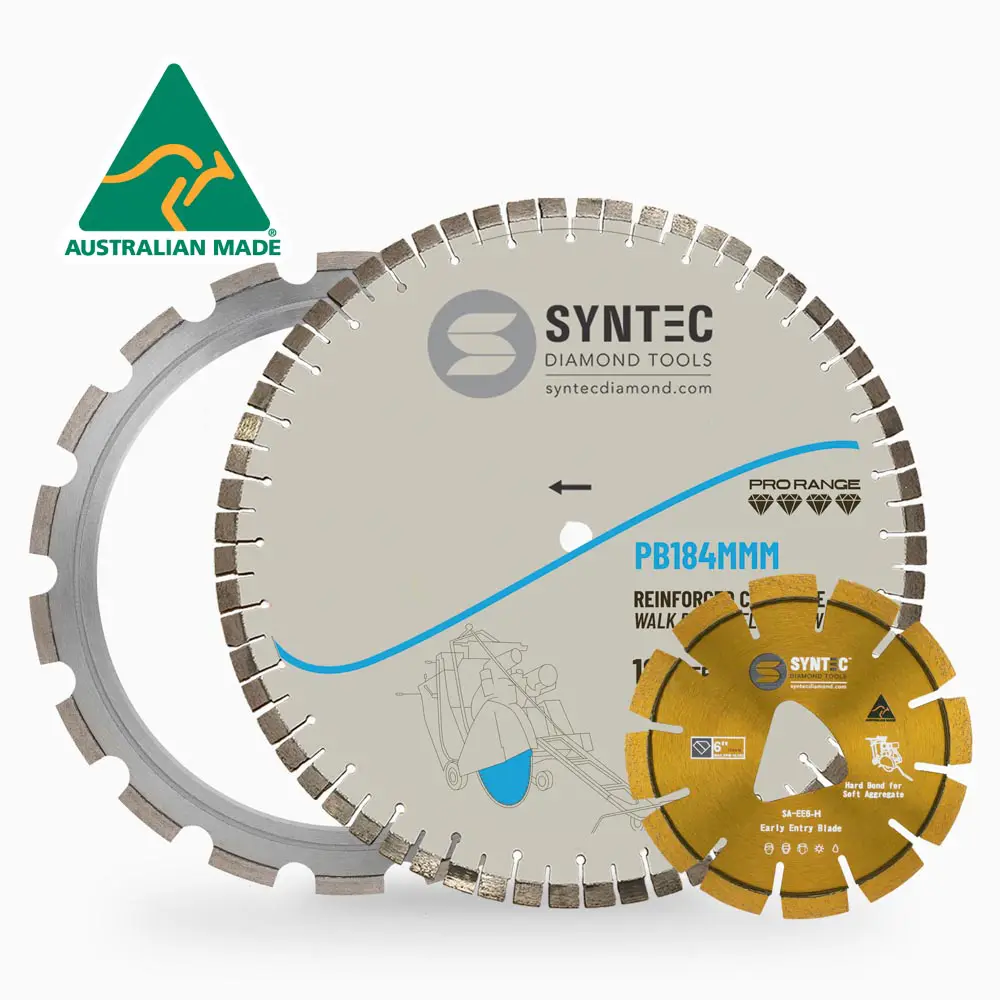

All Syntec Diamond Tools tooling is designed to work wet dramatically reducing exposure to harmful dust.

Equipment

Top Vacuums for Silica Dust Control

HEPA-filtered vacuums – High-efficiency particulate air (HEPA) vacuums are essential because they capture 99.97% of particles as small as 0.3 microns, preventing silica dust from escaping into the air. Leading brands include:

Bosch and DEWALT offer robust options for construction environments.

Festool provides vacuums with adjustable speed controls for versatile use.

Ruwac USA specializes in industrial vacuums with advanced features like external filter shakers to reduce worker exposure and cyclonic pre-separators to prevent clogging.

Wet/dry vacuums – These can handle both dry dust and liquid mixtures, which is useful when silica dust must be combined with water to minimize airborne particles. Some models feature automatic filter cleaning systems to enhance safety and performance.

Direct bagging systems – Systems like those offered by Ruwac prevent exposure during disposal, ensuring workers avoid direct contact with dust when emptying bins.

Recommended Masks and Respirators

For respiratory protection, it’s recommended to use:

P100 respirators – These masks offer the highest protection, filtering out 99.97% of dust particles. Reusable half-mask respirators with P100 filters provide long-term protection, while disposable respirators like the N95 can be used for shorter tasks.

Powered air-purifying respirators (PAPR) – These are considered the best option for heavy exposure. They provide filtered airflow and are more comfortable for extended use compared to regular masks.

By combining high-quality vacuums with appropriate respiratory protection, you can effectively minimize the risks of silica dust exposure and ensure compliance with safety regulations.

View our Range

Diamond Blades

View our Diamond Blade products, including high and low HP blades, wall saw blades, floor saw blades, early entry, and hand saw blades.

Surface Preparation

View our Surface Preparation products, including tooling, resins, cup wheels, grinding plates, and accessories.

Core Bits

Explore our Core Bit range, designed for reinforced concrete, medium, and hard materials, with various sizes, custom options, and accessories.